Basement Upgrades

Over the last weeks (mostly the weekends) I worked on improving our house's basement setup. As you may know (or have inferred from previous posts), our basement has two major rooms. One of them is my workshop, the other is used for laundry and storage.

Flooring

The basement has simple, relatively uneven concrete flooring. When spending multiple hours in the workshop, I found that quite hard on my feet. So I was looking something that might help with that. For the laundry room I also wanted an easier to clean floor.

After considering various options, I finally decided for PVC garage floor tiles. The tiles are easy to put down, provide a bit of shock absorbing but are strong enough to support my heavy work bench.

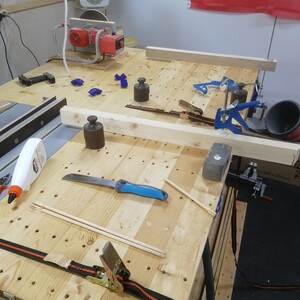

Installing was straight forward, but of course required partly dis- and reassembling the furniture in the workshop. The tiles can easily be cut with a circular or jigsaw and I even used my router table to work around some especially uneven parts in the concrete.

Euro Box Storage

For quite a while we stored lots of stuff in simple cardboard boxes. This of course is a horrible option for long term storage. Especially in the somewhat humid environment of a basement.

Last year I replaced those boxes with Euro boxes. While not cheap, they are sturdy, moisture resistant, can be stacked and are standardized. This means I am confident that I will be able to replace or add more of them in future years.

I built simple roller boards from OSB and caster wheels to easily access the stacks of boxes. Less used stuff (like keepsakes) is further down the stack, while more frequently used stuff (Christmas lights, camping gear) get the upper layers.

Cupboard

The rest of the storage in the laundry room was a pain. It consisted mostly of old Ikea Gorm shelves that I owned for probably more than 20 years. Stuff was haphazardly thrown onto them, everything was super dusty and shit tended to end up on the floors. They also took a lot of space.

Since I had to disassemble the shelves for laying down the floor tiles anyway, it was a good opportunity to tackle the storage.

The first step was to drastically reduce the stuff to be stored itself. Much of it was left overs from the house renovation. Half empty, dried up paint containers, electrical fittings, and other building materials. I was able to throw out quite a bit of stuff.

To replace the shelves, I decided to build a proper cupboard to protect the contents from dust. The construction is a simple frame with OSB doors and sides. The construction was complicated by neither the wood, nor the walls and floors being straight.

The inside shelving was constructed by reclaiming the wood from the old Gorm shelves (using my new thickness planer which should get a separate review).

The new cupboard also houses a new iteration of my can FIFO. It's accessible from the front and side. I used 3mm MDF for the shelves. Wooden rails keep the tins in line and improve the sturdiness.

The hardest part was wrapping my head around how hinges work. Since I didn't use euro-style cabinet hinges but simple butt hinges, I ended up placing them visible on the outside of the doors. To make them flush, I made a jig on my scroll saw that I then used with a copy ring on my router.

The door handles are 3d printed.

Over all the cupboard came out just fine for a basement storage solution but isn't fine cabinet making.

Curver Boxes

Kaddi had a whole bunch of Curver boxes from the nineties which were much to nice to throw away, even though their use case overlaps with the Euro boxes.

So I decided to build another shelf that would use these boxes as drawers. Again I built it from reclaimed IKEA Gorm wood, creating glued up panels for the first time – I need proper panel clamps next time. I had to fill all the peg holes with dowels. Since I didn't have the right size of dowels, I made them myself using a piece of metal as explained in this video.

The only problem with the curver boxes is that they have open handles - you don't want that in a dusty environment. Luckily that is an easy fix if you have a 3D printer.

The bottom shelf houses an aluminium travel box which can easily be moved thanks to a caster wheel tray under it.