Failure is always an Option

I'm still working on improving the workshop and one of the things I'd like to have is a disk sander.

Since desk space is limited, I thought about a DIY solution that would attach to my new drill press. I had seen videos by others who had build something like this and I thought it would be an easy enough project.

The idea is to use a 90° drill attachment to transform the direction of the drill press forward, attach a disk and use a circular lazy susan style bearing to avoid lateral force on the drill press chuck.

The first challenge was to create a disk that is actually perfectly round. My first attempt used the jigsaw. Of course the result was far from a perfect circle. I tried mounting it to the drill press and then sand it round, but this didn't really work either.

So for my second attempt I improvised a circle cutting jig for my router using it's parallel guide. The result was much much better.

To attach the jig, I used a threaded hex shaft. Since the threaded end was longer than my disk was thick, I designed a 3D printed extender. It also has three screw holes for further fastening, but in the end, threading the shaft into the wood and securing it with a screw from the front was more than enough. To insert the shaft at a perfect 90 degrees, I chucked it into the drill press while screwing it in by hand.

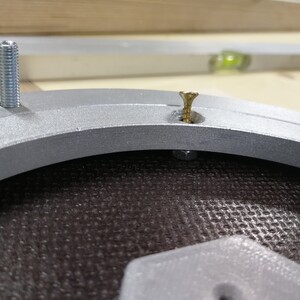

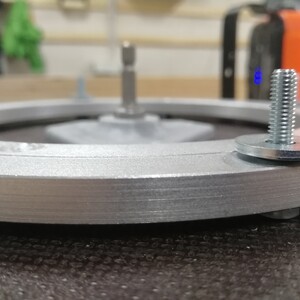

Next was the bearing. The plan was to screw it to the disk with wood screws and use machine screws to mount it to the back plate. But I only had hex headed machine screws, so I had to drill out some space for the heads. Worked fine.

The bearing needs to be mounted so that the shaft is in the perfect center. Otherwise the shaft will wander relatively to the back plate later on.

My first attempt was to simply draw a circle with the proper size and then align the bearing by eye. However that did not work at all.

My next attempt were drilled spacers from the center shaft to the machine screws. That worked a bit better, but it was still not perfectly centered.

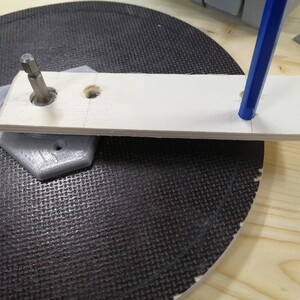

Finally I 3D printed a jig that fit exactly into the bearing, with a M5 hole in the dead center. Attaching the jig then sliding the bearing over resulted in a nearly perfectly centered bearing. And it only took me three days to arrive at that point.

However this high point was also when I finally gave up on the project for several reasons.

During my testing in between, I noticed how awkward it was to mount the mechanism to the drill press. The whole disk sander would als be rather large, maybe still smaller than a “real” one but still…

The final blow to the project however was my first test run. Despite my efforts of perfectly aligning it, the whole thing still caused really ugly vibrations on my drill press.

So instead of continuing working on a solution that would be sub optimal at least and probably too cumbersome to use a lot, I declared defeat and decided to buy a real machine some time.

Frustrating.